The ice-cold best - The ROCKWOOL TECLIT system is a newcomer in the traditional market of cold insulation. Fire safety, energy saving, and circularity are important and are only becoming more important in the future. That is why ROCKWOOL developed the TECLIT system for pipes with a temperature range of 0 to 250 °C, for both hot and cold installations.

Read more: Isolatie Combinatie certified ROCKWOOL® TECLIT specialist

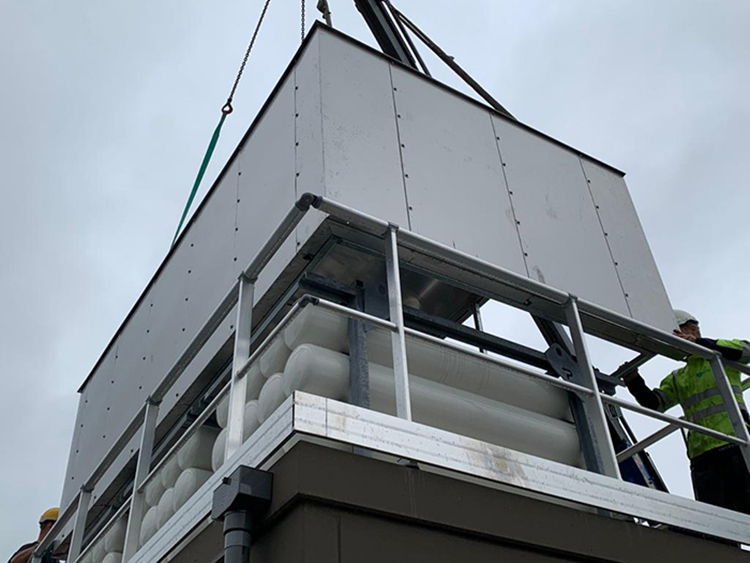

DEN HELDER – ‘Off the ground’, literally and figuratively. A new offshore contractor with plenty of experience was recently established. With a new approach, four specialist maintenance parties will work together under the name Cooperating Offshore Partners BV - abbreviated COP. The partnership can offer offshore operators in wind energy, oil, and gas production many advantages.

COP will offer a complete offshore service package in the field of insulation, constructions, pipes & valves, scaffolding and blasting and painting.

This will make things easier for offshore parties. They will have only one point of contact that takes care of the safe, efficient and expert handling of their projects. Because the maintenance activities are closely coordinated, savings of up to 15% on TCO costs can be achieved.

The partnership

Who are the companies active within COP? First of all, there is Multimetaal Offshore, active in engineering, fabrication, installation and maintenance of constructions, pipes and valves. The second party is Isolatie Combinatie; an experienced industrial insulation company that carries out all insulation work, including the associated engineering. The third party is Steigerbouw van der Panne, a very experienced scaffolding builder who can install safe scaffolding and rope access solutions in even the most challenging locations with a team of experienced builders.

The fourth is SSB offshore; a blasting and painting company focused on the industry and offshore with broad knowledge of (paint) systems to be applied.

In short, the companies within COP complement each other and, in this way, offer a complete solution for a range of diverse maintenance projects.

Extensive experience in offshore

These real family companies together have more than 150 years of experience in offshore. The partners have a high level of staff commitment, short lines of communication and place great value on customer loyalty.

Safe but also sustainable and cost-efficient

Within COP, safety is number one. But working in a sustainable and efficient way and saving costs are of course also important. Cost savings can result from more efficient transport of staff and material to the platforms. Fewer transport movements is also safer. COP also looks at environmentally-friendly sustainability technology.

The advantages at a glance

Offshore operators achieve cost savings thanks to the participating specialists. COP has a great deal of experience and in-depth knowledge of all fields. Furthermore, the offshore operator has a single point of contact for all activities. That’s a big advantage. The specialist employees work together within each other’s disciplines and provide demonstrable security through their certifications and insurances. Is this a reason to further explore COP? The website is already up www.cop-offshore.nl.

We are delighted to announce that, on the 10th of March COP Offshore solutions will commence with the preparation, engineering and execution of the Fabric Maintenance Campaign on three Offshore locations with one of the main operators on the North Sea.

The scope consists of a Campaign approach in the execution of scaffolding, painting, insulation, NDO, engineering and repair of structural steel and piping.

We look forward to a safe, successful and close cooperation!

Are you also interested in the services COP has to offer?

You can contact us on:

+31 (0)88-0245500

Isolatie Combinatie has created a tailor-made fire protection solution for three petrol stations around Paris. The cabinets protect 3 bottle racks with a total of 48 CNG (Compressed Natural Gas) cylinders against potential jet fires.

High quality fire protection, friendly service

The stainless steel cabinets, built using the IGNIS PFP-PANEL principle, provide jet-fire protection to the back and sides of the setup.

To the front, there is a service panel with integrated hatches. These facilitate the performance of inspections and maintenance to the installation. The panels to the protected sides offer 150 minutes of protection from fire and are Lloyd’s certified (no SAS F160347) in accordance with the ISO 22899-1 2007 jet fire standard.

The power of jet fires

Jet fires are one of the most severe types of fires that might occur in the industry. Due to their heat, intensity, and power, these fires are extremely fierce and difficult to extinguish.

CNG is often stored at pressure levels of 200 to 250 bar. In the event of a damaged pipeline or seal, the gas will spray out at high pressure. This creates a risk of direct ignition of the outflowing gas due to static or kinetic energy. To get an idea of what a jet fire looks like, please follow this link to a video:

To keep the situation manageable, it is useful to cover up other sources of flammable materials. This is what the IGNIS PFP fire-protection panels can be used for.

Thermal insulation for LNG

If we compress and cool natural gas even further, we’re talking about LNG rather than CNG. For LNG installations, Isolatie Combinatie develops and constructs cryogenic insulation systems as well, which protect gas, cooled to –162℃, and prevents thermal loss. You can find more information about this insulation under the header Cold & cryogenic insulation.

A solution for your project?

The fire protection and insulation systems manufactured by Isolatie Combinatie are completely tailor-made for your situation. More information about the systems is available on our products page, but you are of course always welcome to contact our advisors / engineers directly to discuss your situation.

Recently, Isolatie Combinatie published a new Case study on noise control solutions in the industrial sector. Many industrial processes that work with high pressures produce a lot of noise. Legal requirements, both for personnel and the environment, require for installations to be equipped with high-quality sound insulation.

Read more: Deafening silence? Sound management for industrial sectors

English

English  Nederlands

Nederlands  Deutsch

Deutsch